Inspection of Storage Tank Bottoms and Corrosion Mapping Via Ultrasonic Testing and Signal Processing Methods

DOI:

https://doi.org/10.58190/icisna.2025.160Keywords:

Ultrasonic Testing, Storage Tank Inspection, Corrosion Mapping, Signal Processing, Peak Detection, Non-Destructive TestingAbstract

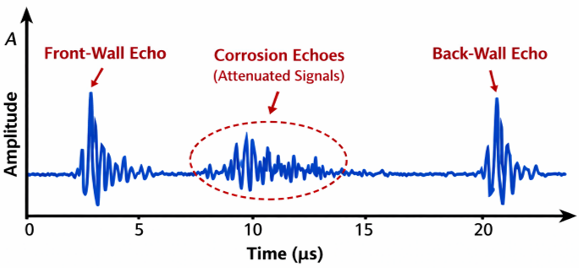

The integrity of storage tank bottom plates is critically affected by corrosion-related material loss, which poses significant risks to operational safety, environmental protection, and asset reliability. Ultrasonic testing (UT) has long been employed as a non-destructive evaluation technique for thickness measurement; however, reliable interpretation of high-density ultrasonic data remains challenging under real field conditions due to noise, surface irregularities, and complex echo patterns.

This study presents an academically oriented framework for the inspection of storage tank bottoms using ultrasonic A-scan data combined with advanced signal processing techniques. Frequency-domain and time–frequency-domain methods, including Fast Fourier Transform (FFT), Short-Time Fourier Transform (STFT), and wavelet-based analysis, are employed to enhance signal quality and improve echo discrimination. A hybrid peak detection strategy integrating adaptive thresholding and continuous wavelet transform (CWT) is proposed to robustly identify corrosion-related reflections.

The extracted thickness data are spatially organized on two-dimensional grids and transformed into three-dimensional corrosion maps using interpolation-based reconstruction techniques. The proposed methodology demonstrates improved robustness in low signal-to-noise ratio (SNR) environments and contributes to a more objective and repeatable corrosion assessment process. The results highlight the potential of signal processing–driven UT analysis as a reliable academic and industrial tool for storage tank integrity evaluation.