Automated Quality Control in Welding Processes Using YOLOv5 and YOLOv8

DOI:

https://doi.org/10.58190/icisna.2025.143Keywords:

Automated quality control, Data augmentation, deep learning, YOLOv5, YOLOv8, Welding defect detectionAbstract

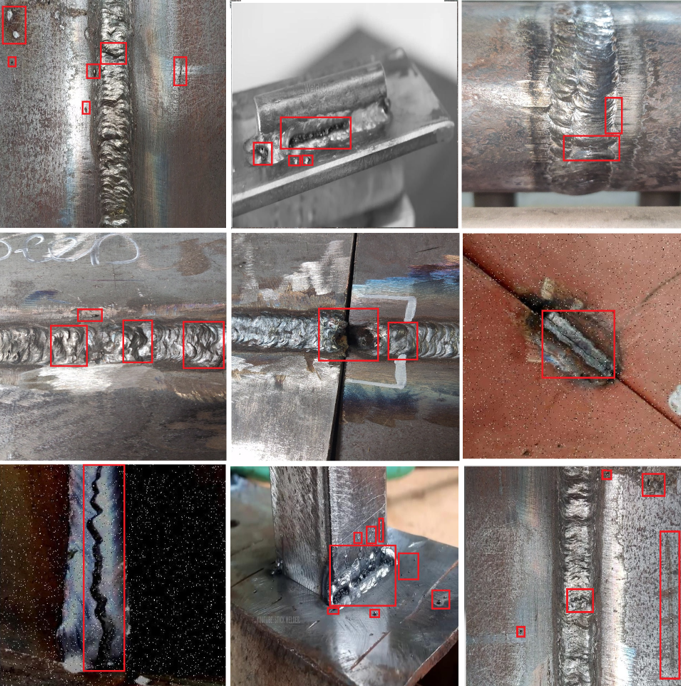

This paper presents a comparative evaluation of YOLOv5 and YOLOv8 object detection models for automated quality control in industrial welding applications. Publicly available welding defect datasets obtained from Kaggle were used, consisting of geometry, structural, and surface defect classes. The dataset was divided into training, validation, and test sets, and all models were trained under identical hyperparameters to ensure a fair comparison. Six YOLO variants—YOLOv5n, YOLOv5s, YOLOv5m, YOLOv8n, YOLOv8s, and YOLOv8m—were evaluated with data augmentation strategies enabled and disabled. Performance was assessed using F1-score and confidence score (CS) metrics on a test set of 75 images. Experimental results demonstrate that data augmentation significantly improves detection performance across all model scales, increasing F1-scores while simultaneously reducing mean confidence scores, which indicates improved model calibration and reduced overconfidence. Furthermore, both YOLOv5 and YOLOv8 architectures demonstrated highly competitive performance, with the medium-scale YOLOv5m achieves the highest F1-score of 0.824, followed closely by YOLOv8m. These findings indicate that modern YOLO architectures provide robust and generalized solutions for real-time welding defect detection tasks, making them well suited for industrial inspection systems.